ГЦС-РОБОТ

Наш телеграм-канал с новостями: https://t.me/cmcrobotkrasnodar

- 8-800-550-6875

- krasnodar@cmc-robot.ru

- Мы работаем без выходных и праздников

Description CMC01 Kit

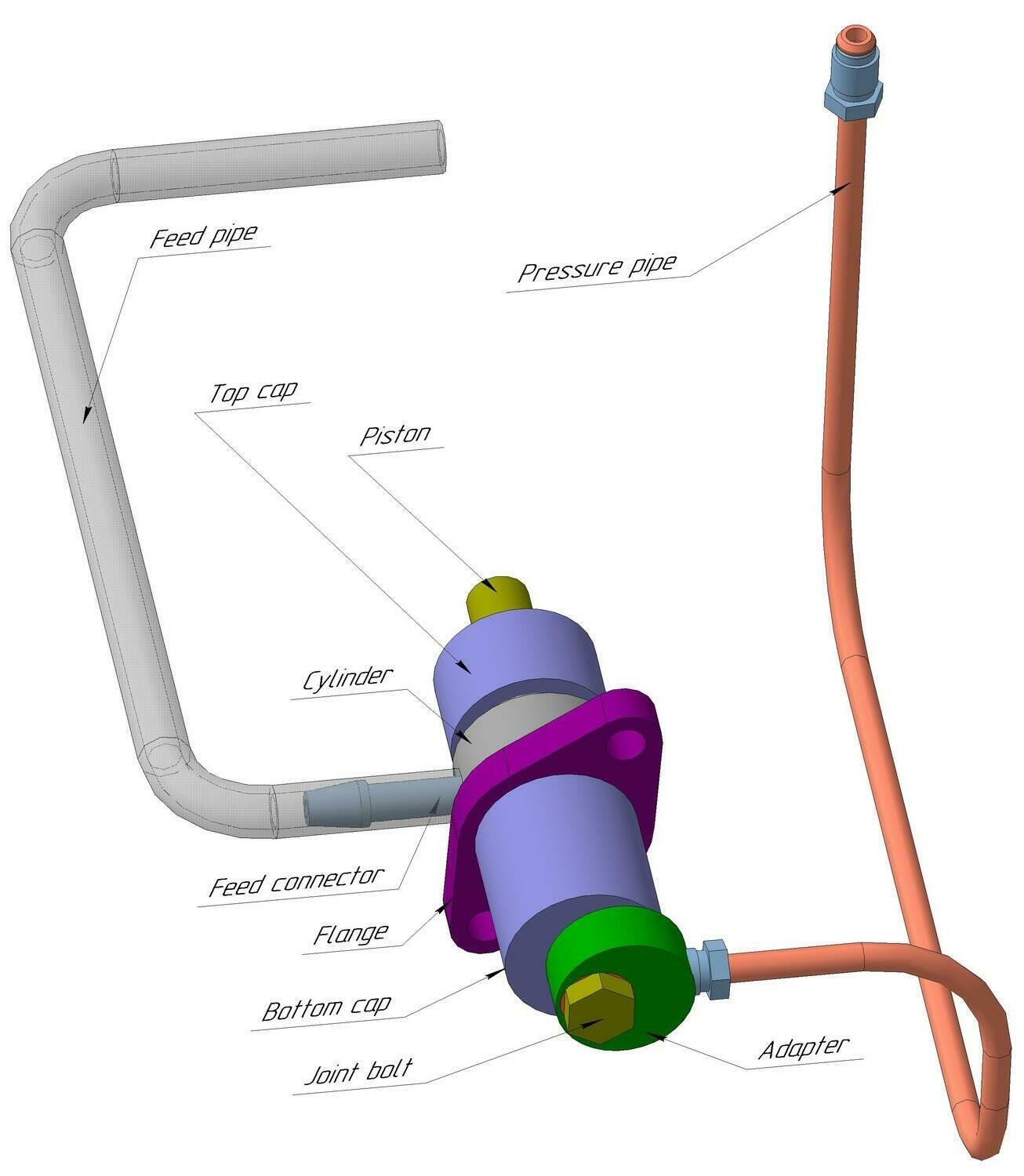

CMC01 kit is intended to use with MTA Easytronic with clutch master cylinder LuK G1D500201, so the kit fits for every car with that type of transmission. It is easy to install at Durashift EST (Ford) also (we will provide special adapter free by your require).

There is no need for kit modifications, completing or testing: it has been tested well already and is ready to be installed.

There are time-tested materials used: corrosion resistive aluminum alloys with and without anodizing, brass alloys also – everything machined with CNC or without. We provide 3 years warranty, anyway the kit can be maintained with relative simplicity (it is easy to overhaul it in minutes with our repair kit).

Reliable type of valve used and it has been tuned for more depressure value than original valve, rigid pressure pipe without flex inserts used also that is why clutch control is much more stable in tough drive conditions (for example, longterm city traffic jams) – it feels easier to drive. Transparent feed pipe is good for fluid contamination control, fast estimating fluid critical level due to expansion tank opacity. Tiny space (0,5 mm) between actuator body and cylinder is an extra barrier for road dust and mud.

Unfortunately, the kit does not rehabilitate worn out clutch and clutch slave cylinder (in gearbox housing).

Download CMC01 Kit Description and Installation Guide

Installation Guide for CMC01 Kit (Easytronic)

1. There is no need for kit modifications or completing. Piston clamp is similar to original clamp, that is why installation principle is the same as for original cylinder.

2. There is no need for additional testing: the kit has been already factory well-tested. Be careful to avoid shooting your eyes with fluid residuals (brake fluid DOT4 used for testing). The kit is pre-assembled and tested in that condition so do not disassemble it.

3. Make sure fluid and friction surfaces are always clean during installation and operation from any type of contamination (oils, fuels, solvents, WD40, etc.) – it is basic requirement for reliable and durable operation of the kit.

4. To install cylinder:

− place actuator push rod to lowest position (rotate shaft manually clockwise till easy resistance to lower push rod) and then raise it up for 10-12 rotates of shaft (rotate shaft manually anticlockwise);

− provide piston position at least 15-20 mm above the cylinder top cap. It is required to lubricate piston with brake fluid DOT4 and move it along its axis repeatedly (so the piston will slide smoother than before lubricating);

− place the cylinder to actuator and make sure the push rod will be guided directly inside piston then tighten the flange of cylinder to actuator body with bolts;

− shortly supply compressed air (up to 8 bar) into pressure (copper) pipe till clamp in the piston snaps push rod (till click sound is heard). Raise up push rod to the upper position (rotate shaft manually anticlockwise till easy resistance to raise push rod). It should be easy for air to pass through the cylinder in any direction (through pressure pipe to feed connector and vice versa), it indicates proper snapping of the push rod in the piston;

− connect feed (transparent) pipe to cylinder and fluid expansion tank. Be sure not to cut this pipe with overtightened clamp;

− screw up pressure (copper) pipe to clutch slave cylinder adapter, it is normal to bend pipe within reasonable limits.

5. Bleed up hydraulic system, check for leaks. Cylinder has some peculiarities in valve design to improve stability of system that is why you should use manual bleeding procedure (“screwdriver method”) for the initial filling with fluid: to avoid excess saturation with air during bleed process (just to make the process faster). It is not allowed to bleed with expansion tank pressurizing method because feed (transparent) pipe is not intended for that.

6. It is recommended (but not always necessary) to adjust clutch with special software after just the kit has been installed. In further let the gear selector stay in “A” position at short stops for transmission to be able self-learning for best shifting.

7. Replace fluid in 1000 kms (about 600 miles) and then − every half a year. It is possible replace fluid by replacing it only in expansion tank periodically without full bleeding procedure, for example, with medical disposable syringe, to keep the fluid clean. Usually there is no necessity in adjusting clutch with special software after fluid replacing procedure.